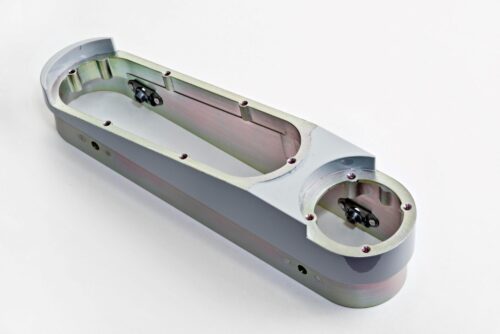

Precision Assembly Parts

When Operational Readiness & Success are the Mission

As the largest provider of Precision Assemblies services to industries Served; Commercial Aerospace, Military & Defense, Telecom, and Medical, Thuro Metal Products has the experience to effectively manage programs for even the most discerning customer.

With thousands of part assemblies manufactured and delivered to BAE Systems per year, Thuro Metal Products (TMP) has a proven track record of performance. TMP was an early proponent of the cost and efficiency benefits that Assemblies provides to the industries we service. Just ask and we’ll prepackage any combination of components at our facilities, and deliver them to you ready for immediate use on your production line. You’ll also have full lot traceability for all components in a bar-coded format.

This specialty leverage TMP’s strengths in the areas of:

- Production Planning

- Demand planning

- Forecasting

- Consumption analysis

- Logistics and transportation management

- Warehouse management

- Flow control

- VMI Vendor Management Inventory

Customized Precision Assemblies combine all tools, parts, and supplies necessary to support the war fighter globally. Keeps our customers GLOBALLY competitive turn to us to develop their Assemblies.

Benefits of Using Thuro Metal Products for Your Precision Assembly Project

- Dedicated assembly area: Highly skilled personnel using specialized tooling and assembly equipment will accurately, precisely and efficiently perform assembly operations and hardware installation.

- Maintaining an extensive supply of standard hardware: Heli-coils, clinch nuts, studs, screws, washers, EMI gaskets, custom captive screws, all types of threaded inserts, panel fasteners, and adhesives.

- Partnership: Our hardware suppliers manage and stock at our point of use decreasing total cost and lead time.

- Increased efficiencies: Minimize time spent pulling parts from inventory or searching for the proper tool. Part assemblies are built and ordered to provide parts when they are needed, so items will not be sitting on your shelf waiting for the rest of the parts to arrive.

- Reduction of Stock: Get only the parts you need, when you need them.

- Reduced item management: The only SKU you need to manage is the precision assembly itself. You order a single part number, which means only one PO, one set of shipping documents, etc.

- Increased flexibility: Assembly/repair lines are not tied to inventory locations. Precision Assemblies are delivered where the work is being done.

- Lean-tested: You will have the required components and tools delivered to the part assembly or repair depot

- Extensive capability in Milling and Turning: Precision components used in assemblies.

- Extensive in-house capable: Wash, polishing, and de burring.

- Maintaining an approved, responsive and highly capable group of post machine vendors: Plating, painting, anodizing, heat treating, grinding and silk-screening.

Assembly Solutions Designed for Complex Program Requirements

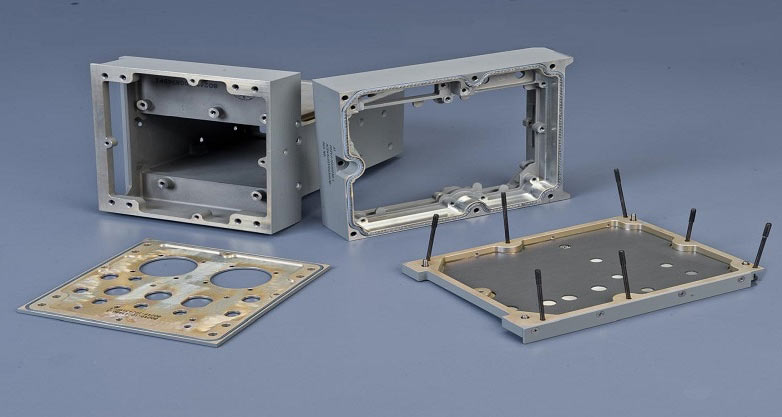

Precision assemblies support OEMs that require coordinated delivery of machined components, hardware, and sub assemblies packaged for immediate use on the production line. Thuro’s assembly capabilities are structured to support industries where readiness, reliability, and configuration control are central to program success. These assemblies are used across aerospace, defense, telecom, and medical applications, where consistent performance and documented traceability are mandatory.

Integrated Assembly Workflows

Thuro manages assembly programs using structured production planning, demand forecasting, consumption analysis, and controlled material flow. Components are packaged, labeled, and delivered as consolidated assemblies, reducing the number of SKUs customers must manage. Bar coded traceability is maintained for each lot, supporting documentation requirements for regulated industries and long term service programs.

Hardware and Component Management

A dedicated assembly area supports hardware installation using specialized tooling and controlled processes. Standard hardware, including helicoils, clinch nuts, studs, washers, threaded inserts, panel fasteners, and adhesives, is stocked at point of use to reduce lead time and simplify replenishment. Supplier managed inventory programs further streamline material flow and reduce administrative overhead.

Operational Advantages for OEM Production Lines

Precision assemblies reduce the time required to pull individual components, verify hardware, or locate tools. By consolidating multiple items into a single part number, customers minimize purchase orders, receiving steps, and documentation. Assemblies can be delivered directly to the work cell, supporting flexible line layouts and reducing dependence on centralized inventory locations.

Machined Components and Post Processing Capabilities

Thuro manufactures the machined components used within assemblies using multi axis turning, milling, and Swiss machining platforms. In house washing, polishing, and deburring support clean, ready to assemble parts. Approved vendors provide plating, painting, anodizing, heat treating, grinding, and silk screening, ensuring assemblies meet program specific requirements.

FAQ

What Types of Programs Benefit from Precision Assemblies?

Programs that require coordinated delivery of machined parts, hardware, and installation materials benefit from precision assemblies. These assemblies reduce handling time and support consistent build processes.

How Is Traceability Managed for Assembly Components?

Each assembly includes bar coded lot traceability for all components. This documentation supports aerospace, defense, and medical requirements where configuration control is important.

What Hardware Can Be Included in a Precision Assembly?

Assemblies can include helicoils, threaded inserts, studs, washers, panel fasteners, adhesives, and other standard hardware. Items are stocked at point of use to support efficient assembly.

How Do Precision Assemblies Reduce Inventory Management?

Customers manage a single SKU instead of multiple individual components. This reduces purchase orders, receiving steps, and storage requirements while improving workflow efficiency.