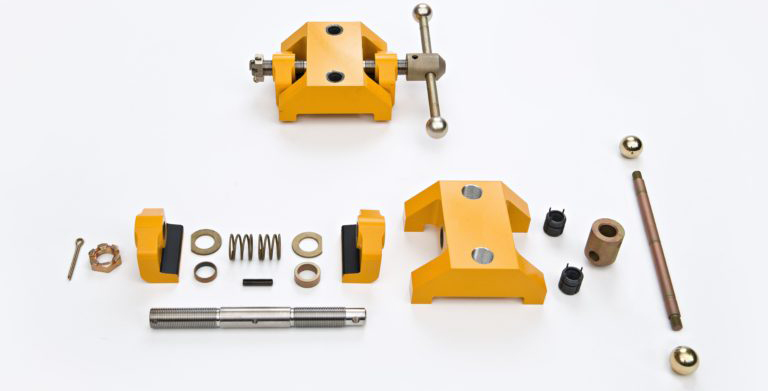

One Thuro Metal Products customer, a leader in safety and cargo restraint products for the aerospace and transportation industries, partners with Thuro Metal Products’ supplement in-house manufacturing capabilities. In this instance, this client approached us with the opportunity to partner in the production of the clamp assembly pictured here. The incumbent contractor, who had previously supplied the Tie-Down assembly and used forging in production process for the main housing, had since gone out of business.

With advances in high-speed machining, Thuro suggested making these high-quality components from solid materials. The availability of the ideal machines to produce each individual component made this project interesting and perfect for the Thuro Metal Products’ production process. Thuro reverse engineered the product using a sample part to process. Our Engineers started with creating operation drawings for numerous components we produce in our factory under one roof. Then Thuro machined custom component parts using three distinct types of machines; the main housing, the shaft and shaft handle, and the hub. The main housing—made of 6061-T6 aluminum– was made in the milling department using CNC horizontal & vertical milling machines. The main shaft and shaft handle were machined in the CNC Swiss turning department. The hub contained cross-holes that needed to be manufactured efficiently; this required a turning/milling center.

A referral came from Gary Hancock, a veteran with over 40 years of experience who said, “I cannot think of a company more adept in terms of having not only the breadth of capability but also the depth of capacity.” To this end, Thuro is AS9100D, ISO9001:2015 and ITAR registered and can handle the variety of materials and services needed for this project, including OSP and assembly for the clamps and hardware required. The top customer, the US DoD, requires extreme precision so the importance of crossing the t’s and dotting the i’s on documentation cannot be understated.

In terms of expense, by machining instead of forging key components, Thuro avoided charging significant upfront tooling costs. No significant “special tooling” also means production does not have to wait months for special tooling to be made, so the impact on timeframe is significant. Our customer stated, “Having a vendor such as Thuro who is equipped to make all the critical components and supply an assembled clamp assembly under one roof enabled us to stay under budget and deliver on time to the Department of Defense.”

Thuro Metal Products takes pride in our work and is ready to take on many different types of projects. We specialize in OSP outside processing: heat treating, plating, prime and paint, and silk-screening. With our state-of-the-art assembly room, we deliver a complete unit directly to our customer assembly line based on OTD. Contact us today to review your project!