Our Facilities

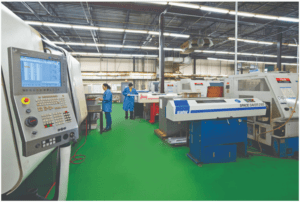

Plant 1: 20,440 sq. ft.: CNC Turning, CNC Milling, CNC Swiss, and Cutting Tool Design and Manufacturing

In 2020 a dedicated precision assembly area was designed and a climate controlled, clean space was built. This new, state-of-the-art precision assembly area considered worker comfort, material storage and workflow from material receipt through shipping. Adjoining spaces were created for incoming components and supplies as well as product shipping. We partnered with Diamond Fasteners and instituted a point of use, vendor managed inventory system (VMI). Our investments in 2020 more than tripled our immediate capacity and permits future growth.

In 2020, we on boarded new team members to staff our new precision assembly department. These experienced professionals brought skill, passion and knowledge. They are highly experienced in the use of automated tooling and techniques, not only with respect to hardware installation but also to permanent part identification. Parts or assemblies used by the Department of Defense often require permanent identification. Our clients are now able to design virtually any type of hardware into their components and we can install it. With our 55 years and extensive turning and milling capabilities, we can cost effectively machine, deburr, polish as well provide plating, painting and part marking services if necessary.

Plant 2, 24,700 sq. ft.: Automatic Screw Machine, Material Sawing, Bar Preparation, Raw Material and Finished Goods Inventory

- Lean Plant Design

- In-House Full-Service Tooling Design and Production Department

- European Craftsmen with 25+ years of experience

- Automated Tool Management System

- Automatic Parts Cleaning System

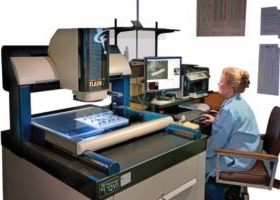

- Automated Vision and Part Coordinate Measuring System